The unique requirements for motors and motion mechanisms in vacuum, high and low temperature, and radiation environments

In various extreme environments, such as vacuum, high and low temperature, and radiation, motors and motion mechanisms face unique challenges that necessitate specialized designs and materials. This article delves into the impacts of these environments on the mechanical performance of motors and motion mechanisms, as well as the effects on lubrication and vacuum discharge, and how a company like Jinshili Technology ensures its products can operate effectively in such conditions.

I. The Impacts on Mechanical Performance

High-Temperature Heat Dissipation: In a vacuum environment, there is no convective heat transfer due to the absence of air. This significantly hampers heat dissipation, causing motors and motion mechanisms to operate at extremely high temperatures. For instance, motor temperatures can reach over 300 degrees Celsius, far exceeding the typical temperature tolerance of 130 degrees Celsius for standard Stepper Motors.

High and Low-Temperature Deformation: In extreme temperature conditions, such as below 0 degrees Celsius or above 50 degrees Celsius, standard motors and motion mechanisms cannot function properly. Special analysis and design are required to account for high and low-temperature deformation. Precision assembly ensures smooth and stable operation of the motion mechanisms, maintaining positional accuracy.

Material Failure in High and Low Temperatures: Common materials become brittle at low temperatures and soft at high temperatures, rendering them ineffective in such environments.

Radiation Decomposition: In radiation environments, motion platforms made of ordinary materials can undergo structural decomposition. This is particularly problematic for motors, which may experience short circuits and operational failures due to radiation decomposition.

Vacuum Cold Welding: In vacuum conditions, materials in contact with each other can adhere due to intermolecular forces if not specially treated. This can significantly impact motion mechanisms.

II. The Effects on Lubricating Grease

Vacuum Environment: The lubricating grease used in standard motors and motion mechanisms can volatilize and contaminate the vacuum environment. For precision equipment operating in high vacuum environments, such as optical devices and mass spectrometers, it is crucial to avoid contamination caused by grease volatilization.

Temperature Sensitivity: The grease used in standard products solidifies at low temperatures, leading to mechanical seizure, and loses its lubricating effectiveness at high temperatures.

III. Vacuum Discharge

Certain components may experience discharge phenomena in vacuum conditions, with corona discharge being more likely in high vacuum environments. Special materials are required to prevent vacuum discharge.

Jinshili Technology's Approach to Ensuring Product Suitability

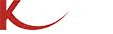

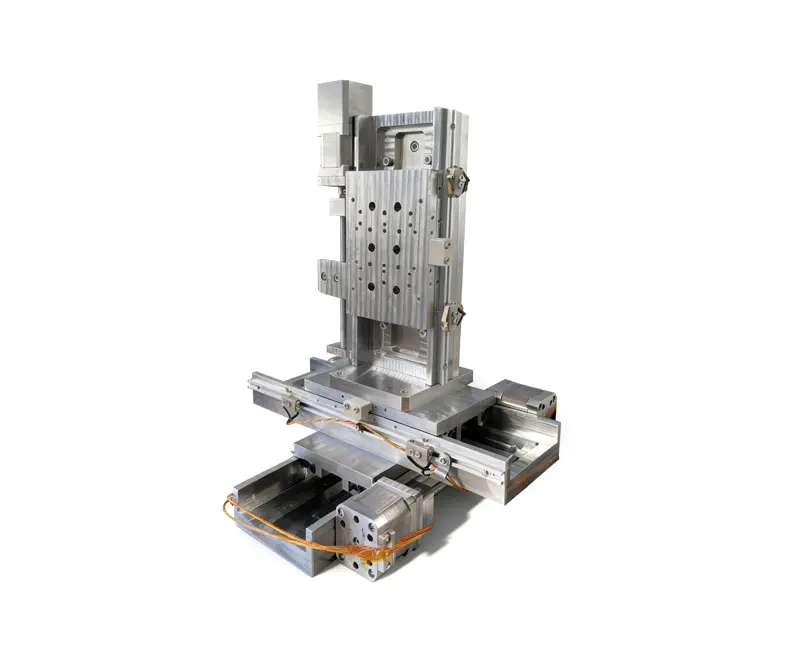

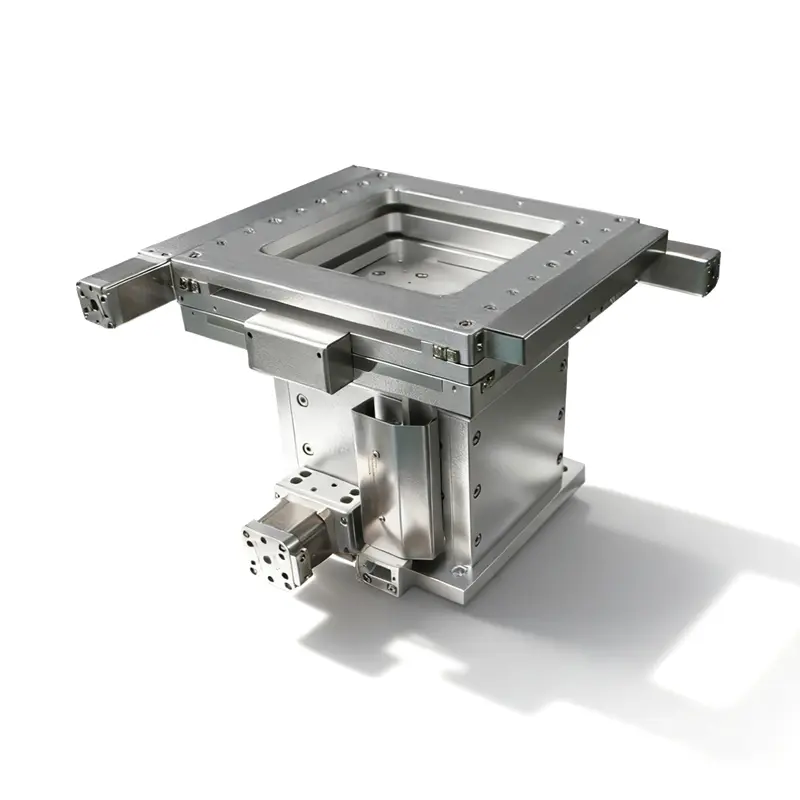

In response to the challenges posed by vacuum, high and low temperature, and radiation environments, Jinshili Technology employs special materials, structural designs, and lubrication techniques for its stepper motors, servo motors, linear motion platforms, reducers, and electric cylinders. These innovations ensure that Jinshili's products can operate effectively in these unique conditions.

In conclusion, motors and motion mechanisms must meet stringent requirements to function reliably in environments characterized by vacuum, high and low temperatures, and radiation. Jinshili Technology's commitment to specialized designs and materials ensures that its products meet these demands, delivering performance and reliability in the harshest of conditions.