TFWS High Precision Five-Axis Test System

Advanced equipment for extreme harsh operating conditions, replacing manual labor to perform precision operations and inspections in hazardous environments.

Company Profile

Chengdu kingsni Technology Co., Ltd. specializes in the research, development, manufacturing, and application of motor drives, mechanical transmission, Motion Control products, and solutions for extreme environments such as vacuum, cryogenic, high temperature, and radiation. With years of technical accumulation and industry experience, we have become a leading supplier of motion control solutions for extreme environments.

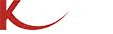

Core Product: TFWS High Precision Five-Axis Test System

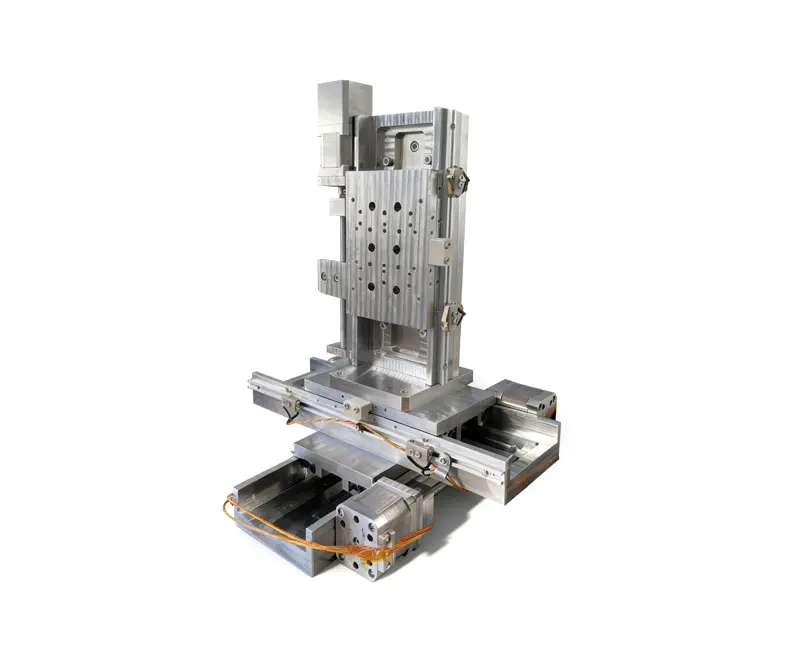

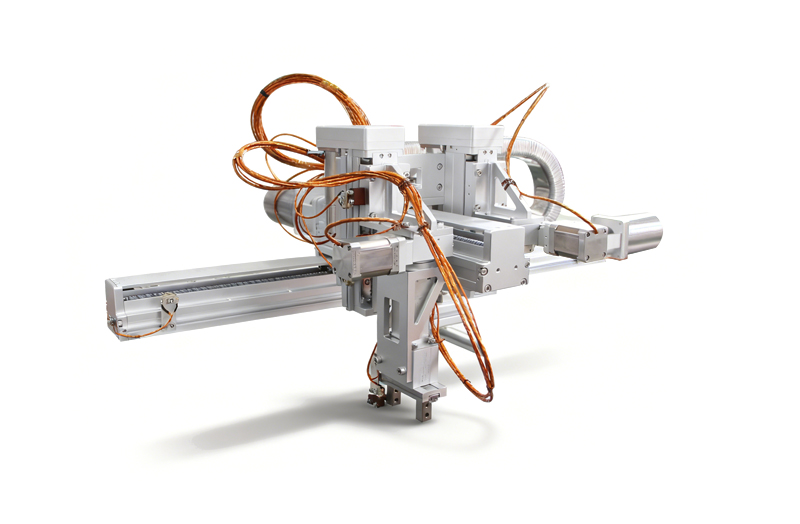

The TFWS High Precision Five-Axis Test System is an advanced piece of equipment designed for extreme harsh operating conditions. It integrates high vacuum (10-5Pa), a wide temperature range (-20°C to +200°C), and ultra-high radiation resistance (106 Gy). It innovatively combines a three-axis translation stage, an R-axis rotation mechanism, and an intelligent gripper into one system, designed to fully replace manual labor, enabling fully automated fuel rod grasping, transfer, and precision inspection within hot cells.

Hazardous Environment Operation Solution

Specifically designed for high-radiation "hot cell" environments where personnel cannot have direct contact. It replaces human operators to perform precise, repetitive, and hazardous sample handling and testing operations.

Core Performance Specifications

- Vacuum Environment: 10-5 Pa High Vacuum

- Operating Temperature: -20°C to +200°C Wide Temperature Range

- Radiation Resistance: 106 Gy Ultra-High Radiation Resistance

- Operational Degrees of Freedom: Five-Axis Coordination (XYZ Three-Axis Translation + R-Axis Rotation + Intelligent Gripper)

Application Adaptability

Its core lies in precise force control feedback and protection mechanisms, ensuring safe and reliable completion of grasping, positioning, and testing tasks on sensitive samples in hazardous environments. Within high-radiation "hot cells" where personnel cannot directly intervene, it replaces humans to perform precise, repetitive, and dangerous sample handling and testing operations, ensuring personnel safety while improving data reliability and work efficiency.

Application Fields

- Nuclear Energy Industry: Nuclear fuel rod handling, radioactive sample inspection, reactor component maintenance.

- Aerospace: Radioisotope power source handling, space radiation environment simulation testing.

- Medical Radiology: Radiopharmaceutical preparation, radiation source replacement, medical equipment maintenance.

- Scientific Research: Synchrotron radiation experiments, high-energy physics research, radioactive material testing.

Safety Protection Mechanisms

- Multi-Layered Safety Protection: Three-level protection with hardware redundancy design, software protection logic, and emergency stop systems.

- Real-Time Monitoring & Alert: Real-time monitoring of system status, automatic alarms and protective measures in case of abnormalities.

- Remote Operation Control: Supports fully remote operation; operators do not need to enter hazardous areas.

- Data Traceability & Recording: Complete recording of all operational data for post-analysis and quality traceability.

Why Choose the TFWS Five-Axis System?

- Personnel Safety Assurance: Completely replaces human entry into high-radiation hazardous environments, ensuring absolute operator safety.

- Exceptional Operational Precision: Five-axis coordinated control achieves micron-level operational precision, ensuring task execution quality.

- Strong Environmental Adaptability: Designed specifically for extreme harsh environments, adaptable to high radiation, high vacuum, and wide temperature range conditions.

- Dramatically Increased Work Efficiency: Enables 24/7 uninterrupted automated operation, significantly improving work efficiency and reliability.

Revolutionary Breakthrough in Hazardous Environment Operations

The TFWS High Precision Five-Axis Test System represents the highest level of technological achievement for automated operations in hazardous environments. In high-risk fields such as nuclear energy, medical, and scientific research, we are committed to providing the safest and most reliable automated solutions for the most dangerous work environments.

"In the most dangerous places, using the safest technology, to complete the most precise operations!"