High-Precision Lifting Solutions for Extreme Environments

As a professional manufacturer of vacuum lifting platforms, Kingsni Technology deeply understands that in high-end fields such as optical instruments, semiconductor manufacturing, and component testing, equipment requires high-precision lifting motion in harsh environments such as ultra-high vacuum, extreme temperatures, and strong radiation. Traditional lifting platforms struggle to meet these stringent requirements, leading to reduced accuracy or even failure of the equipment.

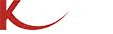

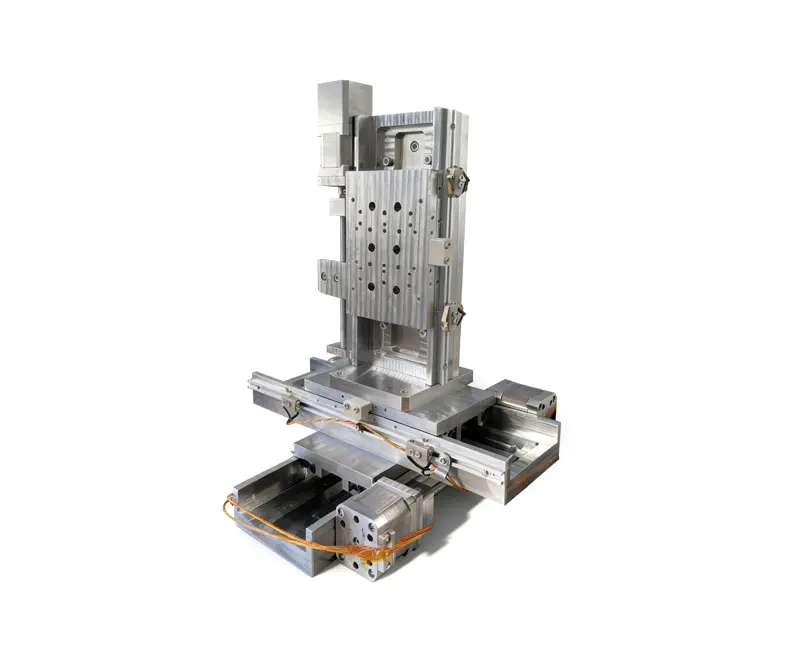

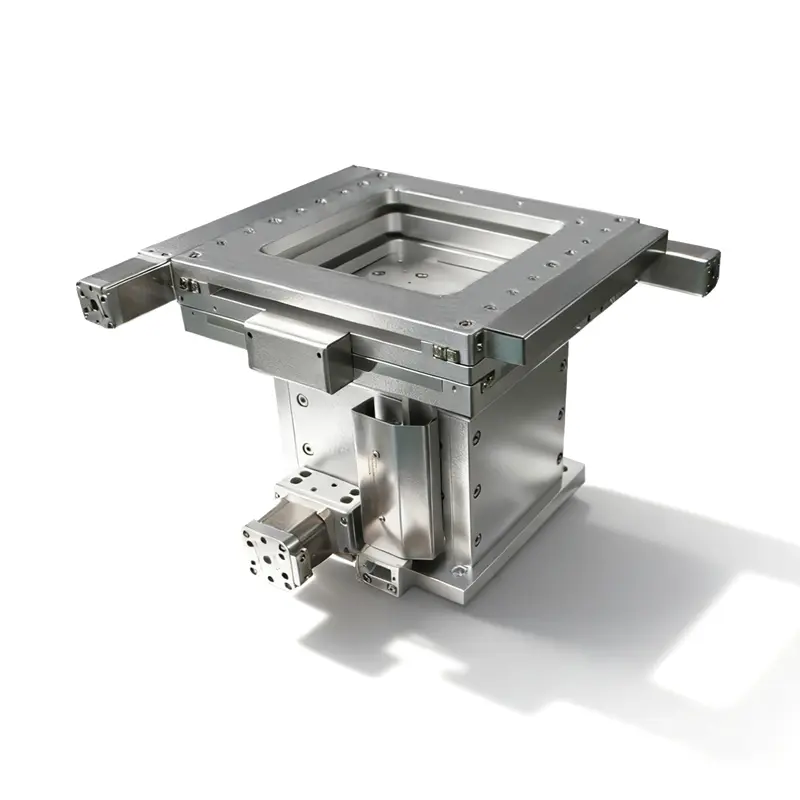

The KZMS series lifting platform, introduced by Chengdu Kingsni Technology Co., Ltd., is primarily used for vertical Z-axis lifting control. It utilizes worm gear and ball screw transmission, guided by four crossed roller guides, featuring mechanical self-locking, high precision, high load capacity, high rigidity, and smooth motion, perfectly solving lifting motion challenges in harsh environments.

Core Keywords:

- Semiconductor Vacuum Lifting Platform

- Cleanroom Vacuum Lifting Platform

- Ultra-High Vacuum Lifting Platform

- Class 100 Clean Vacuum Lifting Platform

- Vibration-Free Vacuum Lifting Platform

- Oil-Free Clean Vacuum Lifting Platform

- Wafer Handling Vacuum Lifting Platform

- Stainless Steel Clean Vacuum Lifting Platform

Core Performance Features

The KZMS series lifting platform adopts special materials, lubrication methods, and structural design to achieve high-precision and smooth motion in extreme environments such as vacuum, deep low temperature, high temperature, and radiation.

1. Extreme Environment Adaptability

- Ultra-High Vacuum Compatibility (10^-7 Pa): Special materials and sealing processes ensure long-term stable operation in vacuum environments.

- Ultra-Wide Temperature Range (-80℃ ~ +200℃): Aerospace-grade materials and lubrication technology adapt to extreme cold and high-temperature environments.

- Strong Radiation Resistance (1×10^6 Gy): Key components use radiation-resistant materials, suitable for nuclear energy applications.

- Cleanroom Compatibility: Optional Class 100 clean design to meet semiconductor and optical application requirements.

2. Excellent Motion Performance

| Parameter | Specification |

| Vacuum Level | 10-7 Pa |

| Ambient Temperature | -80°C ~ +200°C |

| Radiation Dose | 1×106 Gy |

| Transmission Method | Worm Gear, Ball Screw |

| Guide Rail Type | Crossed Roller Guide |

| Table Size | 120×120mm |

| Lifting Travel | Max. 50mm |

| Lifting Speed | Up to 2mm/s |

| Center Load Capacity | Max. 60Kg |

| Lead-out Method | DB9 Socket Centralized Lead-out, Modular Cable |

Typical Application Fields

- Optical Instruments: Precision optical adjustment platforms

- Semiconductor Manufacturing: Wafer handling and inspection equipment

- Component Testing: Sample positioning inside environmental test chambers

- Environmental Simulation Testing: Space environment simulation devices

- Nuclear Energy Industry: Reactor internal component positioning

- Large Scientific Facilities: Synchrotron radiation light source sample stages

- Biomedical: Cell culture and detection equipment

- Research Institutions: Material research experimental devices

Why Choose Kingsni KZMS Series?

- Professional vacuum lifting platform manufacturerwith 10+ years of experience in developing products for extreme environments.

- High-precision design, using crossed roller guides to ensure smooth and precise motion.

- Various specialized models available: Class 100 clean type, ultra-high vacuum type, oil-free lubrication type, etc.

- Fast customization services, providing solutions for special environmental adaptability.

If you need high-precision lifting solutions for extreme environments, please contact the Kingsni Technology team!

Let your transmission system maintain excellent performance even in the harshest environments!