High-Precision Angular Adjustment Solution for Extreme Environments

As a professional manufacturer of vacuum angular displacement stages, Kingsni Technology understands that in high-end fields such as Scientific Instruments, semiconductor manufacturing, and optical inspection, equipment often requires high-precision angular adjustment in harsh environments like ultra-high vacuum, extreme temperatures, and strong radiation. Traditional angular displacement stages struggle to meet these stringent demands, leading to reduced accuracy or even failure.

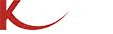

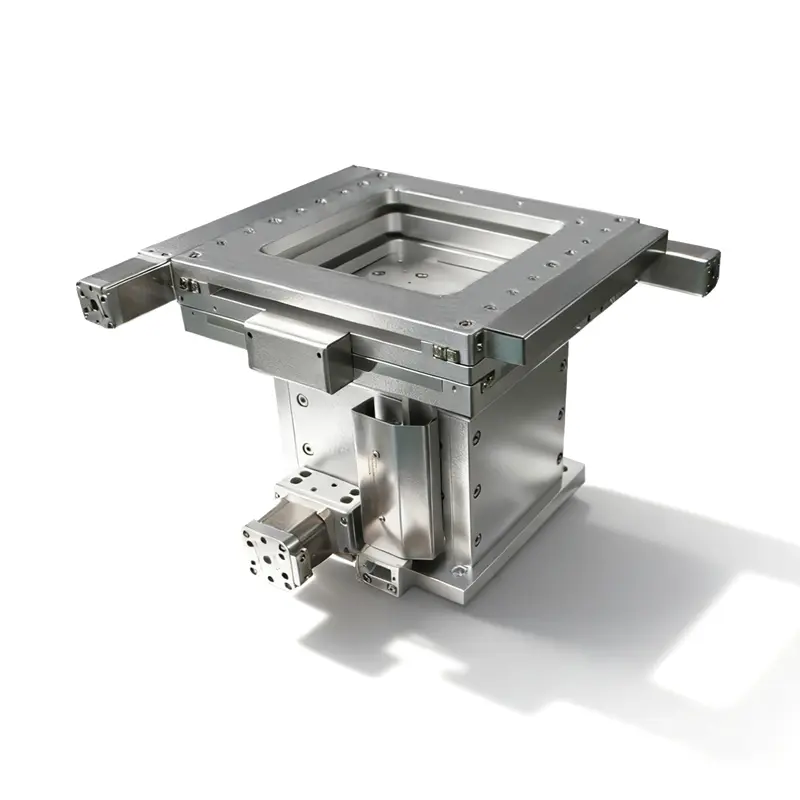

Chengdu Kingsni Technology Co., Ltd. introduces the KAS Series Angular Displacement Stage, specifically designed for extreme environments. Featuring a compact structure, high precision, and long service life, it provides small-angle rotational adjustment for precision motion mechanisms, perfectly solving angular adjustment challenges in demanding conditions.

Core Keywords:

Class 100 Clean Vacuum Angular Displacement Stage

Cleanroom Vacuum Angular Displacement Stage

Ultra-High Vacuum Angular Displacement Stage

Precision Vacuum Angular Displacement Stage

Semiconductor Vacuum Angular Displacement Stage

Class 1000 Clean Vacuum Angular Displacement Stage

Low Outgassing Vacuum Angular Displacement Stage

Oil-Free Clean Angular Displacement Stage

Unique Design Features

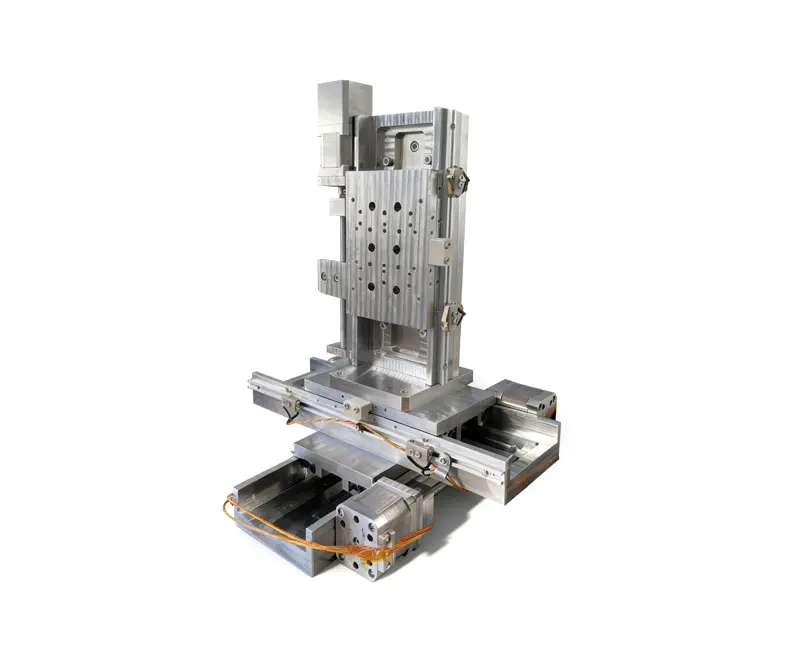

The KAS Angular Displacement Stage utilizes a worm gear and cross roller guide transmission mechanism. Two stages can be stacked to achieve two-dimensional orthogonal rotation around a common point, providing a multi-dimensional angular adjustment solution for precision equipment.

1. Extreme Environment Adaptability

● Ultra-High Vacuum Compatibility (1E-7Pa): Special materials and sealing processes ensure long-term stable operation in vacuum environments.

● Wide Temperature Range (-80°C ~ +200°C): Aerospace-grade materials and lubrication technology adapt to extreme cold and high-temperature environments.

● Strong Radiation Resistance (1×1E6Gy): Key components use radiation-resistant materials, suitable for nuclear energy applications.

● Cleanroom Compatibility: Optional Class 100/1000 clean design to meet semiconductor and optical application requirements.

2. Excellent Motion Performance

| Parameter | Specification |

| Vacuum Level | 1E-7 Pa |

| Operating Temperature | -80°C ~ +200°C |

| Radiation Dose | 1×1E6 Gy |

| Repeatability | ±0.05° (±3 arcmin) |

| Center Load Capacity | Max. 45 Kg |

| Drive Mechanism | Worm Gear, Cross Roller Guide |

| Common Point Rotation | Two stacked stages enable 2D orthogonal rotation around a common point |

Typical Application Fields

Scientific Instruments: Synchrotron radiation sources, Electron microscopes

Semiconductor Manufacturing: Lithography machines, Wafer inspection equipment

Optical Inspection: High-precision optical platforms, Lens testing

Vacuum Coating: Angle adjustment systems for thin-film deposition equipment

Materials Research: Sample stage angle positioning systems

Aerospace Technology: Satellite component testing platforms

Biomedical: Cell imaging angle adjustment platforms

Industrial Automation: Angle adjustment in cleanroom production lines

Why Choose Kingsni KAS Series?

● Professional manufacturer of vacuum angular displacement stageswith 10+ years of experience in developing products for extreme environments.

● High-precision designwith repeatability up to ±0.05°, meeting the needs of precision applications.

● Unique common point rotation design: Two stacked stages achieve two-dimensional orthogonal rotation.

● Rapid customization services, providing solutions adapted to special environmental requirements.

If you need a high-performance angular displacement stage solution for extreme environments, please contact the Kingsni Technology team!

Let your equipment maintain performance in the most demanding environments!