GZXB Multi-Axis High-Precision Positioning and Measurement Platform

High-end testing solution designed for demanding environments, achieving precise measurement and verification of micron-level displacement

Company Profile

Kingsni Technology Co., Ltd. specializes in the research, development, manufacturing, and application of products such as motor drives, mechanical transmission, and Motion Control for extreme environments including vacuum, deep low temperature, high temperature, and radiation. With years of technical accumulation and industry experience, we have become a leading supplier of motion control solutions for extreme environments.

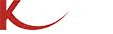

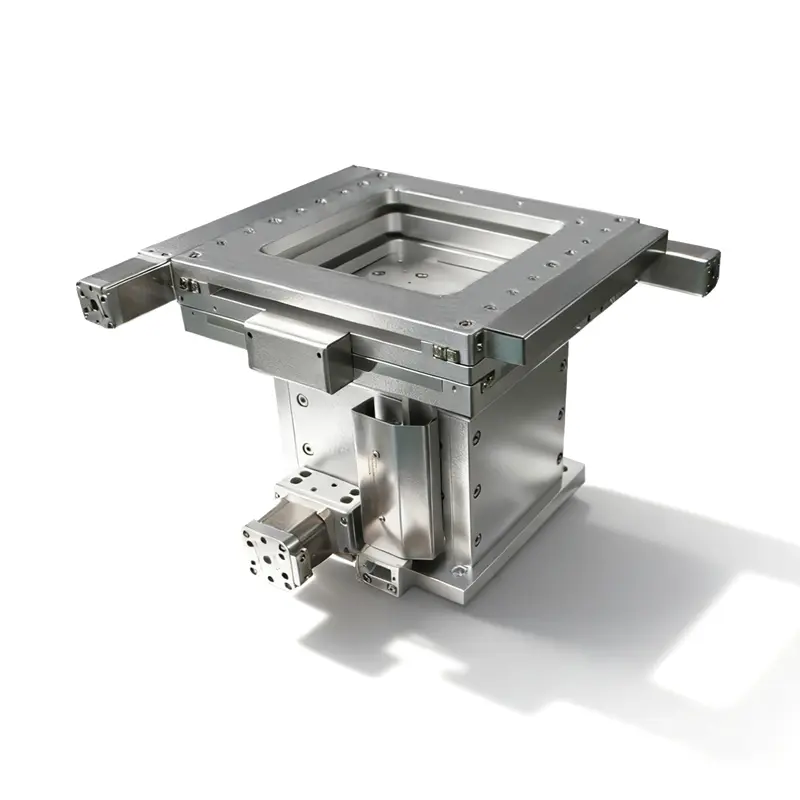

Core Product: GZXB Multi-Axis High-Precision Positioning and Measurement Platform

The GZXB Multi-Axis High-Precision Positioning and Measurement Platform is a high-end testing solution designed for demanding environments. It integrates high-low temperature (-60°C to +120°C), vacuum (10-3 Pa) environment simulation, and multi-axis coordinated motion control. It provides customers with precise positioning measurement under complex motion paths, as well as accurate measurement of parameters such as deformation and accuracy, making every micron-level displacement quantifiable and verifiable, safeguarding your precision manufacturing.

Core Performance Specifications

Temperature Range

-60°C to +120°C

Vacuum Environment

10-3 Pa

Measurement Accuracy

Micron-level

Motion Control

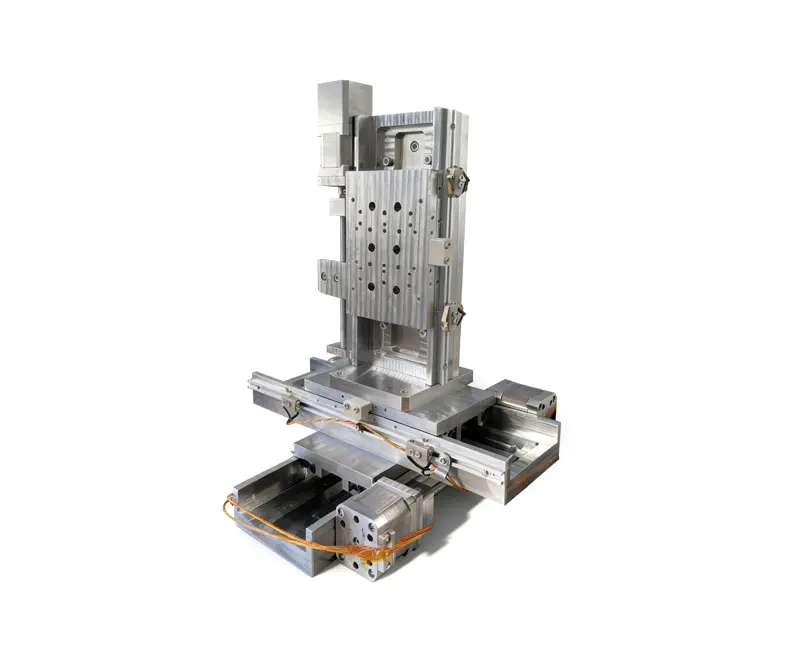

Four-axis coordination (R-axis rotation + three-axis linear servo)

Application Adaptability

Through the unique design of "R-axis rotation positioning + three-axis linear servo," precise positioning measurement of miniature component angles and positions is achieved, ultimately performing micron-level or even nanometer-level measurements via a high-precision grating system, simulating real working conditions.

Application Fields

- Aerospace:Performance testing of spacecraft precision components, satellite mechanisms, key components of aviation engines

- Precision Manufacturing:Quality inspection of microelectronic devices, precision optical components, MEMS devices

- Scientific Research Experiments:Materials science research, precision measurement experiments, extreme environment simulation

- High-End Equipment:Key component testing for semiconductor equipment, precision instruments, medical devices

Typical Test Samples

- Miniature Bearings:Rotation accuracy and life testing under extreme environments

- Precision Guide Rails:Motion accuracy verification in vacuum and high-low temperature environments

- Optical Components:Deformation and displacement measurement under temperature changes

- MEMS Devices:Motion characteristic analysis of micron-level structures

Why Choose KINGSNI GZXB Series?

- Extreme Precision:Micron-level measurement accuracy, meeting the most stringent precision manufacturing requirements

- Environmental Adaptability:Specifically designed for extreme environments, simulating real working conditions

- Intelligent Control:Advanced multi-axis coordinated motion control algorithms

- Customization Services:Provide personalized solutions based on specific customer needs

Opening a New Era of Precision Measurement

The GZXB Multi-Axis High-Precision Positioning and Measurement Platform is not just a testing device; it is the guardian of your product quality. In fields such as aerospace, precision manufacturing, and scientific research, we are committed to providing reliable technical support for every micron-level advancement.

Let every micron-level movement be precisely captured and verified!