For Extreme Environments KVM Series Two-Phase Hybrid Stepper Motors

For Extreme Environments KVM Series Two-Phase Hybrid Stepper Motors

High-Reliability Drive Solution Designed for Extreme Environments

In high-end fields such as semiconductor manufacturing, biomedical, nuclear energy industry, and aerospace technology, equipment often needs to operate stably under extreme conditions including ultra-high vacuum, cryogenic temperatures, high temperatures, or strong radiation. Conventional motors in such environments are prone to lubrication failure, material deformation, and electromagnetic performance degradation, leading to equipment failure or even safety hazards.

Chengdu Kingsni Technology Co., Ltd. has developed the KVM Series Two-Phase Hybrid Stepper Motors through years of technical accumulation, specifically optimized for harsh environments to provide high-precision, long-life motion control solutions.

Core Advantages of KVM Series Motors

1. Adaptable to Extreme Environments, Stable and Reliable

- Ultra-high vacuum compatible (10⁻⁷Pa): Special sealing design and low-outgassing materials prevent vacuum contamination, suitable for semiconductor coating, space simulation equipment, etc.

- Wide temperature range operation (-196℃ ~ +200℃): Maintains stable performance in liquid nitrogen cryogenic or high-temperature baking environments, meeting requirements for superconducting research, high-temperature industrial furnaces, etc.

- Radiation resistant (1×10⁶Gy): Key components use radiation-resistant materials, suitable for nuclear reactor inspection equipment, radioactive medical instruments, and other scenarios.

2. High Performance and Flexible Configuration

- Holding torque 0.04~6Nm, covering various needs from precision fine-tuning to heavy-load driving.

- Multiple functional options:

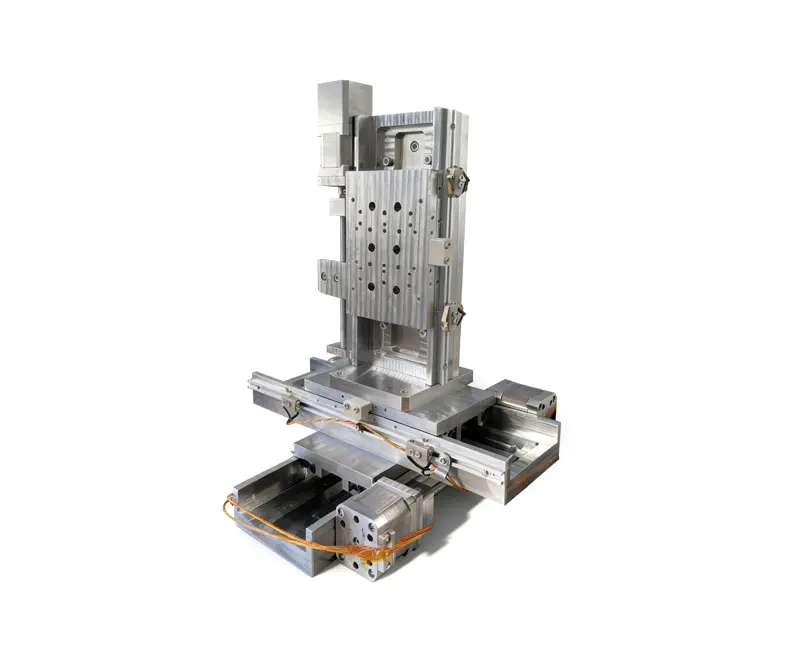

Dual shaft output: Saves space and enables synchronous driving.

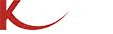

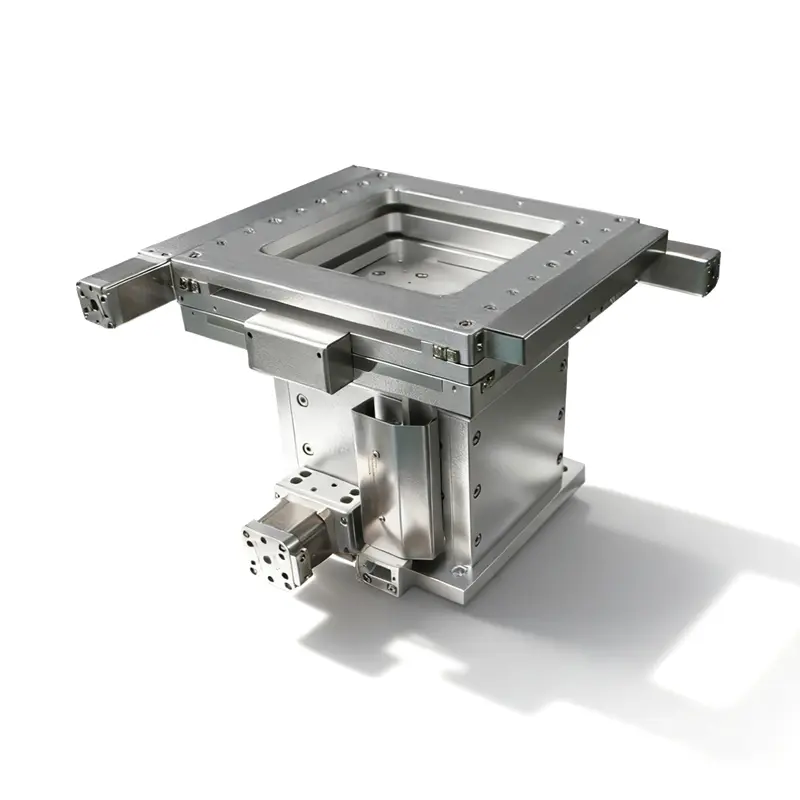

Ball screw integration: Directly achieves high-precision linear motion.

Safety brake: Self-locking when power is off, preventing accidental displacement.

Position feedback: Improves closed-loop control accuracy and system reliability.

Handwheel adjustment: Facilitates manual fine-tuning and debugging.

3. Long-Life Design, Low Maintenance Cost

- High-vacuum grease or solid lubricationprevents volatile contamination and extends service life.

- Standardized flange sizes (28/42/57/86mm)for easy installation and system integration.

Typical Application Fields

Semiconductor Manufacturing: Thin film deposition, wafer transfer & alignment, etching, ion implantation, wafer measurement

Electronic Equipment: Three-temperature testing of electronic components, 3C product environmental simulation testing

Nuclear Energy: Reactor control rod drive, hot cell multi-axis grasping mechanism, nuclear waste treatment

Scientific Instruments: High-energy synchrotron radiation source, optical alignment platform, mass spectrometer sample stage positioning, high-resolution electron microscopy

Aerospace Engineering: Space environment simulation testing

Biomedical: Deep cryogenic storage for biological samples, automated plasma cold storage, automated radioactive drug dispensing

Automotive Manufacturing: High/low temperature environmental simulation testing for automotive components

Vacuum Process Equipment: Ion beam polishing, vacuum coating, vacuum welding, femtosecond laser processing

Defense Industry: Radar turntables, automatic leveling mechanisms, rocket rudder control

Why Choose Kingsni?

- Over 10 years of experiencein extreme environment automation product design, manufacturing, and application integration

- Modular designsupports customized configurations to meet special requirements

- Complete extreme environment motion control product line(motors, drivers, controllers, sensors, mechanical transmission, etc.), providing one-stop solutions

- Diverse service models: Component supply, complete system integration