DZBDT High-Load Ultra-High Vacuum Positioning Stage

Company Profile

Kingsni Technology Co., Ltd. specializes in the research, development, manufacturing, and application of products such as motor drives, mechanical transmission, and Motion Control for extreme environments including vacuum, deep cryogenic, high temperature, and radiation. With years of technical accumulation and industry experience, we have become a leading supplier of motion control solutions for extreme environments.

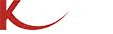

Core Product: DZBDT High-Load Ultra-High Vacuum Positioning Stage

The DZBDT High-Load Ultra-High Vacuum Positioning Stage is a cutting-edge positioning system designed for high-end manufacturing and scientific research. It operates stably within a wide temperature range of -30℃ to +100℃ and an ultra-high vacuum environment of 10-5 Pa, capable of carrying a heavy load of 40kg while performing complex "precision rotation - dual-axis linkage" motions. Its core technology lies in the adoption of grating closed-loop control, ensuring micron-level repeat positioning accuracy with every movement, even under heavy loads and extreme environmental conditions.

The DZBDT High-Load Ultra-High Vacuum Positioning Stage is the "Unshakable Pillar" in heavy-load precision motion. In the most demanding environments, it provides the most reliable motion reference for the most critical components, transforming grand engineering concepts into verifiable, quantifiable precision data, assisting national major scientific projects and high-end equipment manufacturing towards excellence.

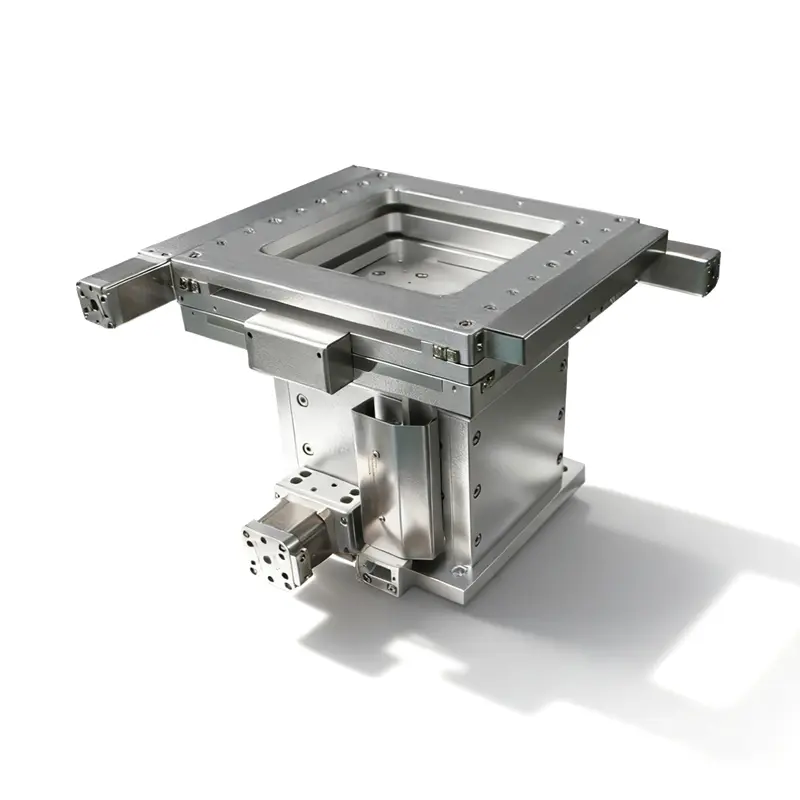

Core Performance Indicators

Operating Temperature Range

-30℃ to +100℃

Vacuum Environment

10-5Pa

Maximum Load Capacity

40kg

Repeat Positioning Accuracy

Micron-level

Application Adaptability

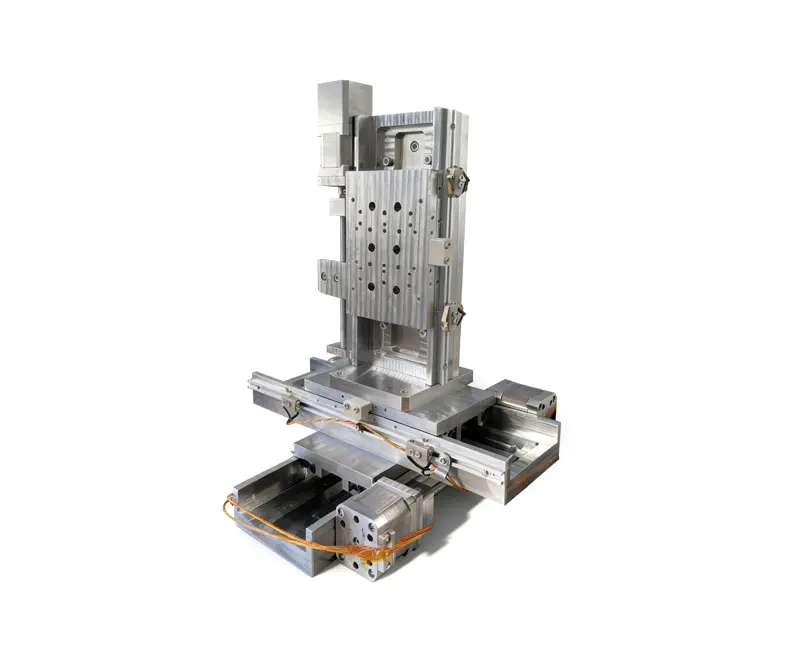

This positioning stage features high load and vacuum compatibility, grating closed-loop precision control, and extreme environmental adaptability:

First, Precise Attitude Positioning:

The R-axis first slowly rotates the optical component to a preset reference angle.

Second, Nanometer-Level Positioning:

Through grating closed-loop control, the entire load is moved smoothly and precisely to the theoretical "absolute zero position."

Application Fields

- Aerospace:Precision assembly of large spacecraft components, satellite payload testing, positioning of key aero-engine components

- Scientific Research Experiments:Synchrotron radiation light sources, particle accelerators, precision positioning systems for large scientific facilities

- High-End Manufacturing:Semiconductor lithography equipment, precision optical processing, heavy-duty industrial robot positioning

- Precision Measurement:Large-scale metrology equipment, precision instrument calibration, material testing platforms

Why Choose the DZBDT Platform?

- Exceptional Load Capacity:40kg high load capacity meets heavy-duty equipment precision positioning requirements

- Superior Environmental Adaptability:Specifically designed for extreme environments, adaptable to the harshest working conditions

- Outstanding Positioning Accuracy:Grating closed-loop control ensures micron-level repeat positioning accuracy

- Intelligent Motion Control:Supports complex motion modes including precision rotation and dual-axis linkage

The Pinnacle of Heavy-Load Precision Motion Technology

The DZBDT High-Load Ultra-High Vacuum Positioning Stage represents the highest level of heavy-load precision motion control technology. In key fields such as aerospace, scientific research experiments, and high-end manufacturing, we are committed to providing the most reliable precision positioning solutions for the most demanding environments.

Pursuing excellence in extremes, achieving precision under heavy loads!