Brakes for stepper motors and servo motors

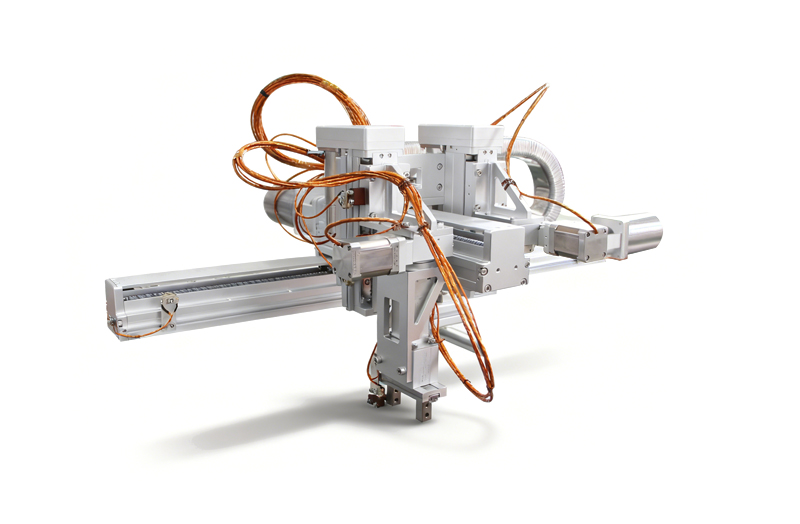

Brakes for Stepper Motors or servo motors serve as a safety device, primarily functioning to provide sufficient static locking torque to the drive motor shaft in vertical motion mechanisms. This prevents the motor shaft, without a brake, from being in an unlocked and free state when the system unexpectedly loses power, potentially causing the load to fall due to gravity.

For stepper or servo motors equipped with brakes, it is crucial to ensure that the brake is in the released state during operation (typically achieved by connecting a 24V power supply to the brake coil). When the motor is powered on but not rotating, the position of the motor shaft is locked by magnetic force. The motor stops rotating based on control commands, not by engaging the brake.

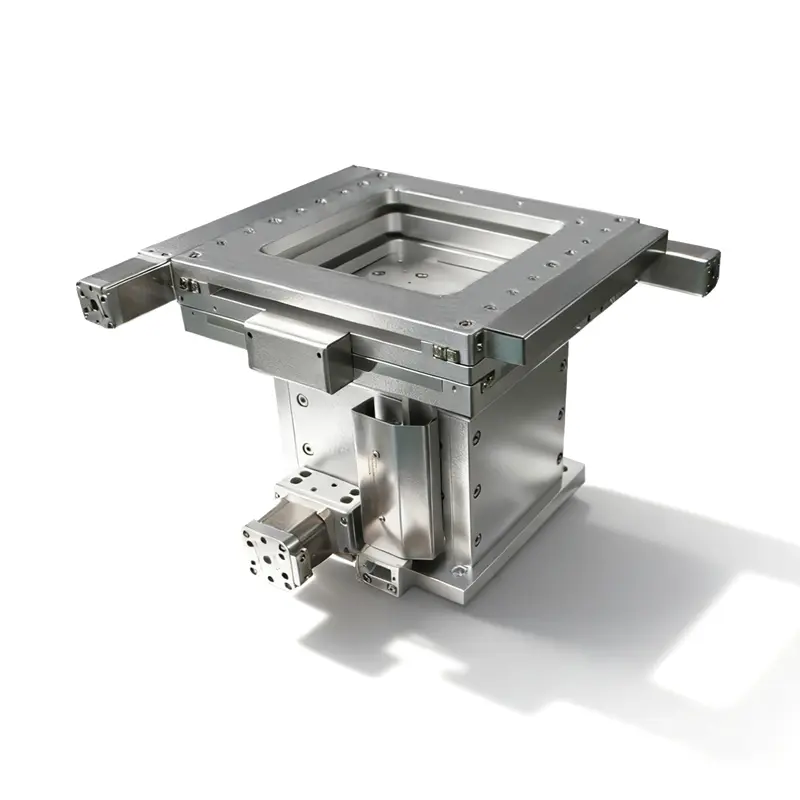

Generally, mechanisms with horizontal motion do not require motors with brakes, while those with vertical motion are recommended to use motors with brakes. However, there are two vertical motion scenarios where motors without brakes can be considered, but careful calculation and thorough assessment of safety risks are necessary:

Vertically installed trapezoidal screw drive mechanisms: If the lead of the trapezoidal screw is small enough to provide reliable self-locking, the motor does not require a brake.

Vertically installed ball screw drive mechanisms: If the lead of the ball screw is small (e.g., 2 or 4mm) and the load weight is light (e.g., 1-2 kg), the large friction torque of the ball screw can prevent the load from slipping, and thus, the motor does not require a brake.

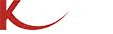

Jinshili Technology's KH series stepper motors and KECM series servo motors can both be equipped with brake options. When selecting a motor for a specific application, engineers should consider the specific requirements, including the need for a brake based on the motion type and load conditions, to ensure the safety and reliability of the system.